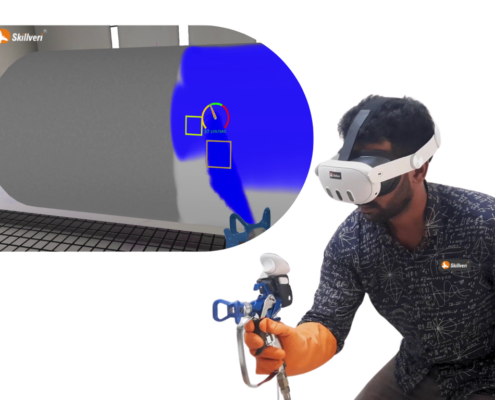

Learning proper repair techniques takes time and repetition. Virtual reality simulations can provide technicians with opportunities to gain experience without needing materials for the work.

Our belief is, when it comes to training fresh learners, teach them to not just paint, but to paint in the most efficient way possible

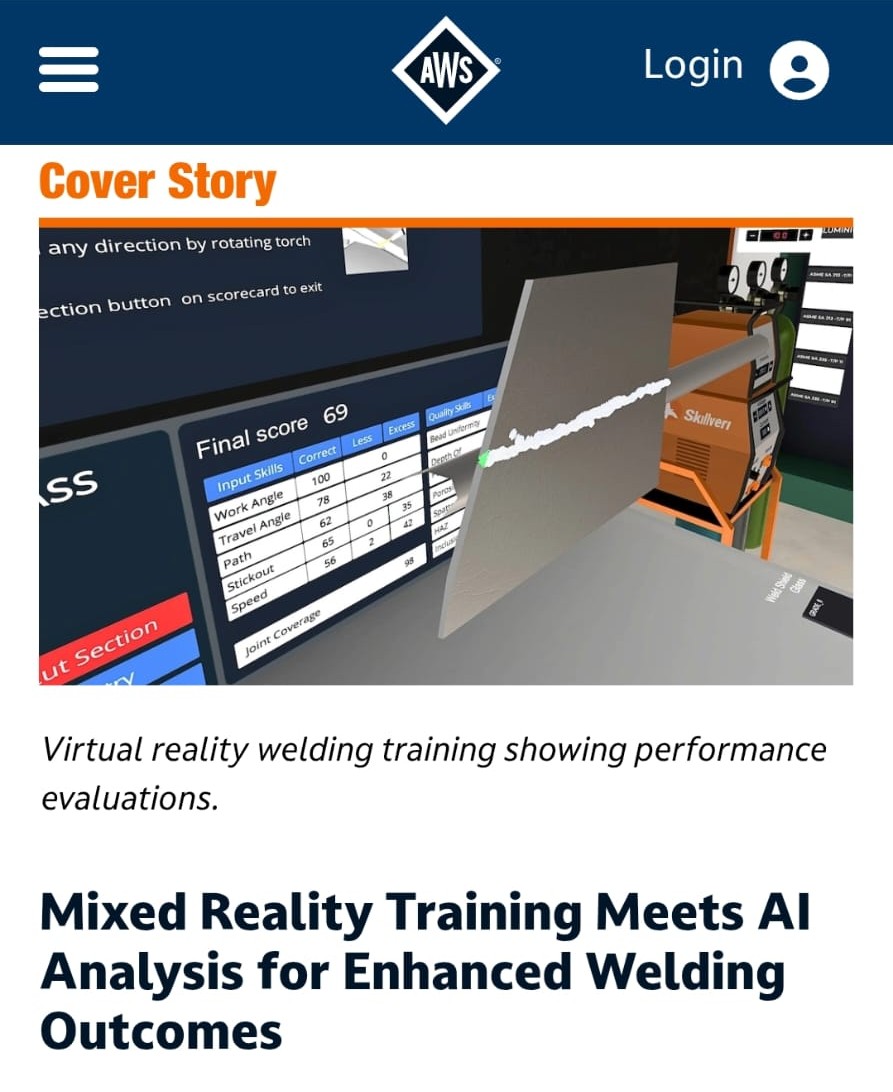

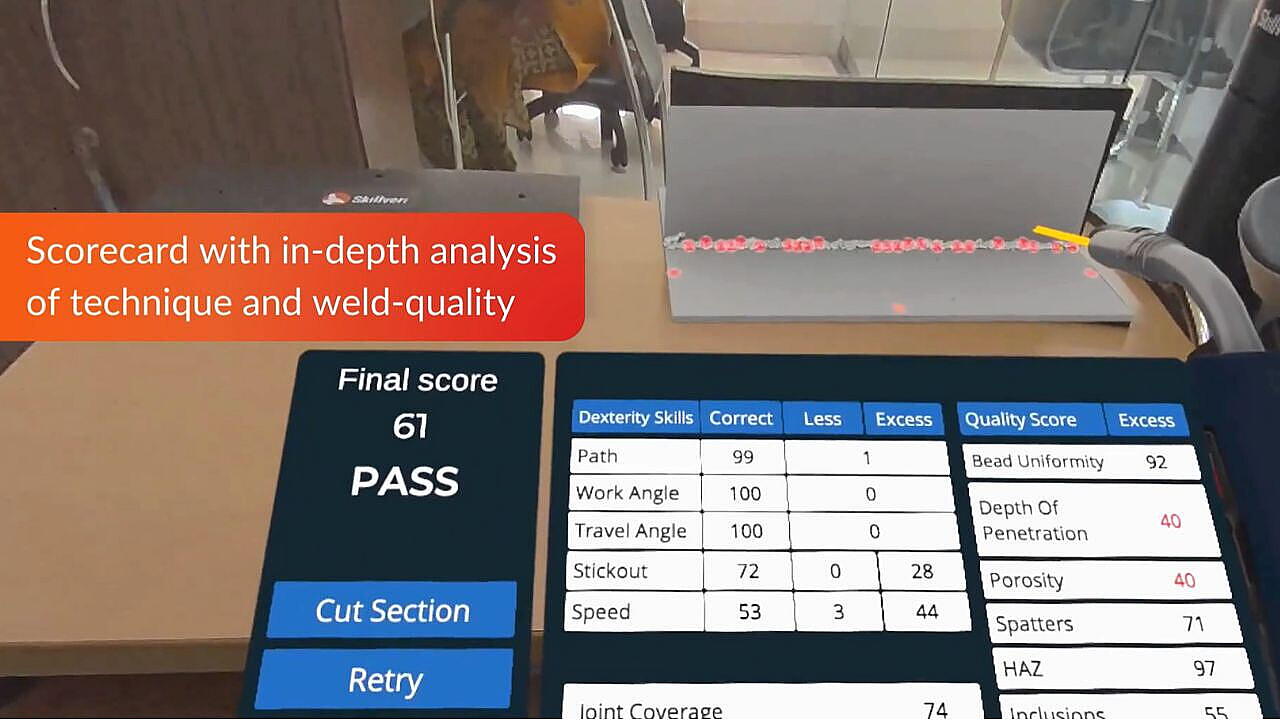

Welding is a critical process that drives progress across industries worldwide. And behind every high-quality weld is the skill of a welder. Training traditionally conducted through apprenticeships, classroom instruction, and hands-on experience has seen increased adoption of technologies such as virtual reality (VR) in recent years. VR platforms simulate welding environments, including plate thickness, multiple joint positions, and gas selections, enabling trainees to practice safely and receive feedback on their techniques. Detailed tracking of hand movement using technology allows evaluation of multiple parameters

VR and AI are no longer ‘future tech’ for skilled trades, they’re becoming the default starting point for practice.

In this deep-dive chat with Nathan Latka, Skillveri CEO Sabari Nair talks on how schools in the USA are making Skillveri VR MR simulators part of their CTE training programs for welding, spray painting, etc.

Skillveri, a tech-first innovator that’s redefining vocational skills training for the next generation workforce, is the third largest provider of immersive simulation-based training in the USA. Skillveri builds multi-skill simulation platforms using XR, VR & MR to offer gamified training modules for skills like welding, spray painting, and HVAC.

The growing gap between the industry requirement of skills and what the workforce has is expected to result in 2.1 million manufacturing jobs going unfilled by 2030.

The critical question to be addressed is, “How can tech be utilized to make employees more efficient?” The focus needs to be shifted from tech vs. employees to tech for employees.

Modern technologies like virtual reality (VR) and mixed reality can be very effective in scaling up training and workforce development, especially for critical areas where both the cost of mistakes and cost of training is very high.

Skillveri is transforming vocational skill training in India and abroad with XR simulators. Built to deliver high-fidelity, measurable outcomes, these simulators replicate real-world tools and scenarios with remarkable accuracy. Learners benefit from gamified, learner-centric modules while industries gain cost-effective, scalable solutions. Compared to conventional training, Skillveri reduces training time by two-thirds and cuts material wastage by up to 80%.

VR/MR is no longer the stuff of science fiction—it’s the future of skill development. Out of the 90 million new jobs anticipated in India by 2030, a staggering 70% will fall under the blue-collar category. These workers form the backbone of industries such as manufacturing, logistics, and construction. In this rapidly evolving landscape, Mixed Reality (MR) is emerging as a game-changer, offering immersive, hands-on training that efficiently bridges the skills gap.

Skillveri’s mission is a belief that technology can fundamentally alter the way vocational skills are acquired. We are not just a tech company; we are a movement to redefine blue-collar work. Our simulation platforms are not merely tools for instruction—they are purpose-built environments that build real confidence and precision in every worker.

India’s youth population is one of its greatest strengths. Yet, a gap in skill levels, access to training, and awareness of opportunities has kept this demographic from fulfilling its potential. Seeing training as a non-essential expense has far-reaching implications. Skillveri CEO Sabarinath Nair writes on how technology offers a transformative solution to India’s skilling challenges. Extended Reality (XR) and Virtual Reality (VR) are now revolutionising technical and vocational education and training (TVET), making training more experiential, effective, engaging, and cost-efficient.

The skill level of the workers directly affects the output quality in industries. An imperfectly executed job can easily result in rejections of an entire batch or result in stoppage of conveyors etc which can run up losses in crores in a matter of hours. Skillveri welding and painting simulators exactly replicate the workpieces and scenarios to give the learner a real world like feeling but eliminating any of the risks and hazards of the real-world training.

Skillveri’s VR and XR simulation platform provides skill training for multiple skills like welding, painting, and other skills like HVAC and solar panel installation. With a fully 3D immersive VR experience, Skillveri welding simulators, painting simulators etc solve skill-gap problems with 100% eco-friendly training and cost savings upto 70%

The advanced XR and analytics provide error-free dexterity training, and measurable evaluation to industries.

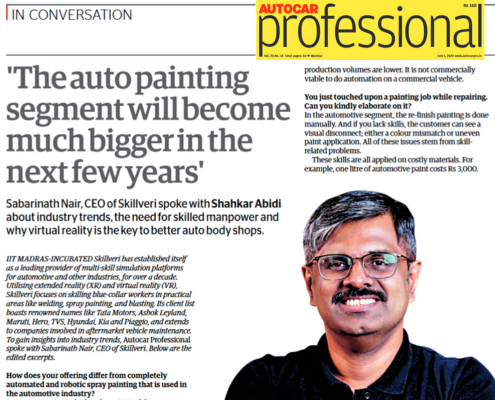

In the ever-evolving landscape of automotive manufacturing, innovation remains the cornerstone of industry advancement. By blending human expertise with robotics, Skillveri is fundamentally transforming the manufacturing landscape, pushing the boundaries of efficiency, precision, and skill development.

Having made significant strides in welding solutions, the company’s journey into the automotive sector was a natural progression.

Immersive technologies (like VR/XR) and AI hold much potential for skill development in a country like India, which has a large manufacturing sector and a large youth demographic. Contrary to popular belief, technologies like these can be quickly scaled and deployed at multiple locations and taken to even remote or rural areas easily. It can thus be the key to bridging the rural-urban divide, enabling a large section of youth everywhere to receive the same kind of training and skilling opportunities available to those in urban centres.

Immersive technologies (like VR/XR) and AI hold much potential for skill development in a country like India, which has a large manufacturing sector and a large youth demographic. Contrary to popular belief, technologies like these can be quickly scaled and deployed at multiple locations and taken to even remote or rural areas easily. It can thus be the key to bridging the rural-urban divide, enabling a large section of youth everywhere to receive the same kind of training and skilling opportunities available to those in urban centres.

Skillveri leverages VR/XR technology to provide efficient, scalable, and cost-effective vocational training solutions, particularly for civil engineering skills like welding & spray painting.

In civil engineering related skills including welding and spray painting, where the cost of imperfect skills can be high, and often more than just monetary, this has significantly enhanced the quality of learning delivered, and brought down the costs and time of training for the employers.

Technology like VR/XR enables workforce in industries like automotive manufacturing and refinish to be trained better, with skills on par with industry requirements. Precise measurement and evaluation of skills also becomes a possibility with VR led training

வெல்டர், பெயிண்டர் உள்ளிட்ட ப்ளூகாலர் தொழிலாளர்களின் திறனை சிமுலேஷன் முறையில் அதிகரிப்பதுதான் எங்களின் நோக்கம். சிமுலேட்டரை பயன்படுத்தி பயிற்சி எடுக்கும் போது சிக்கல் எதுவும் இருக்காது. ஒவ்வொரு முறை வெல்டிங் செய்யும் போது ஏற்படும் முன்னேற்றம் அனைத்தும் இந்த தொழில்நுட்பத்தை பயன்படுத்தி தெரிந்து கொள்ள முடியும்.

இந்த பயிற்சியில் விபத்து என்பதே கிடையாது. மேலும் மூலப்பொருள் வீணாவது இல்லை. இந்த வகையான சிமுலேட்டர் பயிற்சிக்கு அமெரிக்கா உள்ளிட்ட பல நாடுகளில் நல்ல வரவேற்பு உள்ளது.

சிமுலேஷன் மூலம் பயிற்சி கொடுக்கும்போது எங்கு தவறு நடக்கிறது. எப்போது சரியாகும் என்பதை கணக்கிட்டு துல்லியமாக பயிற்சி அளிக்கலாம். மேம்பாடும் அடைய முடியும். மேலும், பயிற்சியில் முழுமையான தேர்ச்சி அடையும்பட்சத்தில் வேலை கொடுத்தால் போதும். சேர்ந்த முதல் நாளில் இருந்து அவரால் சிறப்பாக செயல்பட முடியும்.

Skillveri decided to leverage Meta’s advanced hardware and focus on building the mixed and virtual reality training programmes. Using the company’s proprietary software, workers can be taught welding, spray painting, and HVAC and solar panel installation.

While the start-up is based in India, it has operations in the U.S. and Europe. Combined, it has over 400 installations, and has trained 2.5 million people with its tools since its inception about a decade ago.

Skillveri’s success lies in using advanced XR models to mimic the workshop environment similar to how trainers & trainees interact with it in the real world.

The subtle nuances like the change in sound with a correct or incorrect weld, which trainers know from years of experience – we have tried to replicate that with the use of technology. We made our welding simulators to be a trainer’s aide rather than just a welding machine equivalent.

Skillveri CEO Sabarinath Nair talks to Hindustan Times Tamil about AR, VR & XR. He speaks on how learning through technology like XR and VR simulators will deliver a huge change in skill training for welding, painting etc and create more employment opportunities in the future.

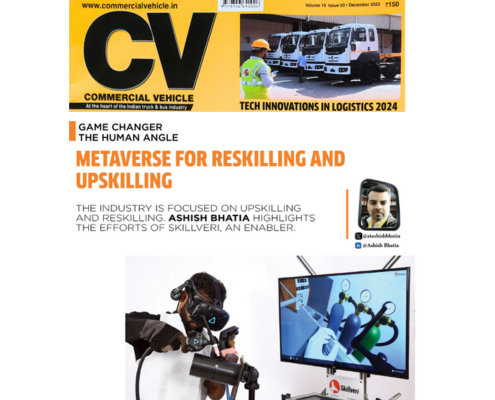

Skillveri is an enabler, banking on the Metaverse to help the industry adapt and meet the requirement for a skilled workforce in a changing landscape. Using technology like XR/VR welding and painting simulators enables precise assessment across several key parameters, identifying areas for improvement and tracking the progress of a learner.

Nov 2023, Manufacturing Today : Metaverse mastery: Skillveri’s rise as a global simulator powerhouse

95% of Skillveri’s US revenue is in SaaS. Customers can buy off-the-shelf VR headsets and download their software from the App Store and get a license.

95% of Skillveri’s US revenue is in SaaS. Customers can buy off-the-shelf VR headsets and download their software from the App Store and get a license.

Modern construction is intricately complex, demanding a workforce equipped with a diverse range of skills, encompassing architectural design and hands-on building proficiency. Skillveri, incubated at IIT Madras and boasting over a decade of industry experience, is at the forefront of using AR and VR to redefine skill acquisition and bridge knowledge gaps in construction. Their Multi-Skill Simulation Platforms on XR and VR are recognized globally as some of the most widely used simulators. The advanced extended Reality (XR) technology, which combines VR, AR, and MR, provides high-quality training for various hands-on skills such as welding, spray painting, and blasting

In this interview with Motor Vikatan, leading Tamil magazine on the automotive sector, our CEO Sabarinath talks on how Skillveri XR simulators for welding, painting, etc are changing the game, improving job opportunities, and transforming the automobile industry. Tech interventions like Skillveri VR welding simulators are reshaping vocational education, enhancing quality, and boosting productivity in the manufacturing sector.

Companies have to spend a large amount of both time and money in training their workforce. Imperfect or poor quality training also impacts the companies by increase in cost of rejections & reworks on the shop floor, as well as resulting in loss of crucial man-hours. Skillveri’s training simulators help companies train more workers in much less time & costs. It also provides them an exact assessment of the learning acquired, and can help decide if the learner needs more practice in a particular area.

Typically users save 60-80% of the consumables cost. Further, there’s reduction in material costs and labour costs due to reduced mistakes from better training. It also reduces the number of days spent on training, both in training centre and on the job.

Skillveri CEO Sabarinath Nair spoke to Tejasvi Sharma, the Chief Editor & MD of EPC World. The conversation highlighted how Skillveri, using VR for welding simulators, painting simulators etc has impacted the quality of training in critical sectors like construction, power plants, and automobiles – where the quality of output can severely impact not just costs but also result in safety incidents.

Sabari elaborated on how Skillveri’s VR/XR simulators carefully track & map hand movement with a precision of 0.2mm, and provide detailed analytics for learning which is not possible in conventional training.

“For hands-on practical skills, XR simulators can not only train but also evaluate dexterity skills. This method has helped most customers to save an average 30-40 percent on rejections and rework-related costs,” said Sabarinath C Nair, CEO of metaverse skill training platform Skillveri.

The other factor is the ability to simulate a conveyor belt on the shop floor for painting. It is economically impossible to have a conveyor system just for training purposes, and internal training centres usually train on stationary objects and not objects moving on a conveyor. In XR, this can be simulated, saving crores of rupees in costs of stoppage of conveyor due to mistakes.

There are big opportunities in automotive, manufacturing, and construction sectors, but there arent enough Indians taking it it up. Sabarinath resolved to do something about the blue-collar gap – he researched the realm, visited factories to understand problems, and then worked to build simulation products to train blue collar workers in areas like welding and painting.

Skillveri aims to disrupt the shopfloor experience. It is incorporating skilling future talent using the latest XR technology, which not only promises to bring the feel of a real manufacturing setup but also does away with raw material wastage. And in fact, while it has been closely working with automotive companies in India, the global markets is expected to be its next frontier of growth.

Skillveri has installed 20 virtual reality stations across 3 centres of Copiah-Lincoln Community College, Mississippi, USA.

They are meant to enrich the training that students will receive under the guidance of Co-Lin’s knowledgeable instructors.The students will benefit from the ability to practice as often as needed, along with the instantaneous feedback the system provides. In addition, Co-Lin will be able to cut material costs and reallocate the funds to other training needs.

Our CEO Sabarinath Nair speaks to The Hindu Business Line on Skillveri’s journey. Starting by addressing challenges in skill development and building an industry-focused platform for manufacturing sector skills like welding and spray painting, Skillveri has now expanded to over 500 installations world-wide.

Nearly 55 schools in the US rely on the simulation platform supplied by the IIT Madras incubated Skillveri Training Solutions Pvt Ltd to train their students in vocational skills like welding, painting, or air conditioner repair. Having succeeded in the US, the company is now looking at the domestic market by supplying its platform to various governments.

Chennai-based Skillveri Training Solutions is aiming to expand its business in the US and Europe as the recent spate of geopolitical events have increased the demand for its training solutions in these markets.

While the electronic and software advancements within welding machines have reduced the dependency on human error, the welder’s hand movement is still a critical factor, and to bring robotic-level precision to that, Metaverse training will help. Training welders in Virtual Reality / Metaverse has opened up a lot of options that were earlier not possible.

With smart manufacturing gaining traction in industries, workers need to have the right skills so that they do not become the weakest link. Technology-based solutions complementing brick-and-mortar training centres can work together to bridge the skill gap. If harnessed realistically, virtual reality (VR) & Metaverse can skill India towards its smart manufacturing dream.

Metaverse is a boon to the education sector, as it helps in creating engaging digital classrooms, retaining students’ attention, provide an interactive learning environment, along with activities like workshops, projects, and experiments, that happen in real-time, enabling effective student participation.

Metaverse is a boon to the education sector, as it helps in creating engaging digital classrooms, retaining students’ attention, provide an interactive learning environment, along with activities like workshops, projects, and experiments, that happen in real-time, enabling effective student participation.

Metaverse is a boon to the education sector, as it helps in creating engaging digital classrooms, retaining students’ attention, provide an interactive learning environment, along with activities like workshops, projects, and experiments, that happen in real-time, enabling effective student participation.

Sep 2022, Skillveri CEO Sabarinath Nair speaks at FICCI Global Skills Summit

Skillveri CEO Sabarinath Nair spoke on the “Future of Skilling” at the FICCI Global Skills Summit. He covered various aspects like mismatch between youth aspirations and opportunities available, realizing their full potential, training delivery through technologies like Metaverse, XR, VR etc for immersive learning.

Skillveri CEO Sabarinath Nair talks with Taslish Chadha on using VR Simulators in Skill Training, for skills like Welding and Spray Painting.

Skillveri CEO Sabarinath Nair : ” Technologies have to be seen as a means to an end, instead of an end in itself.”

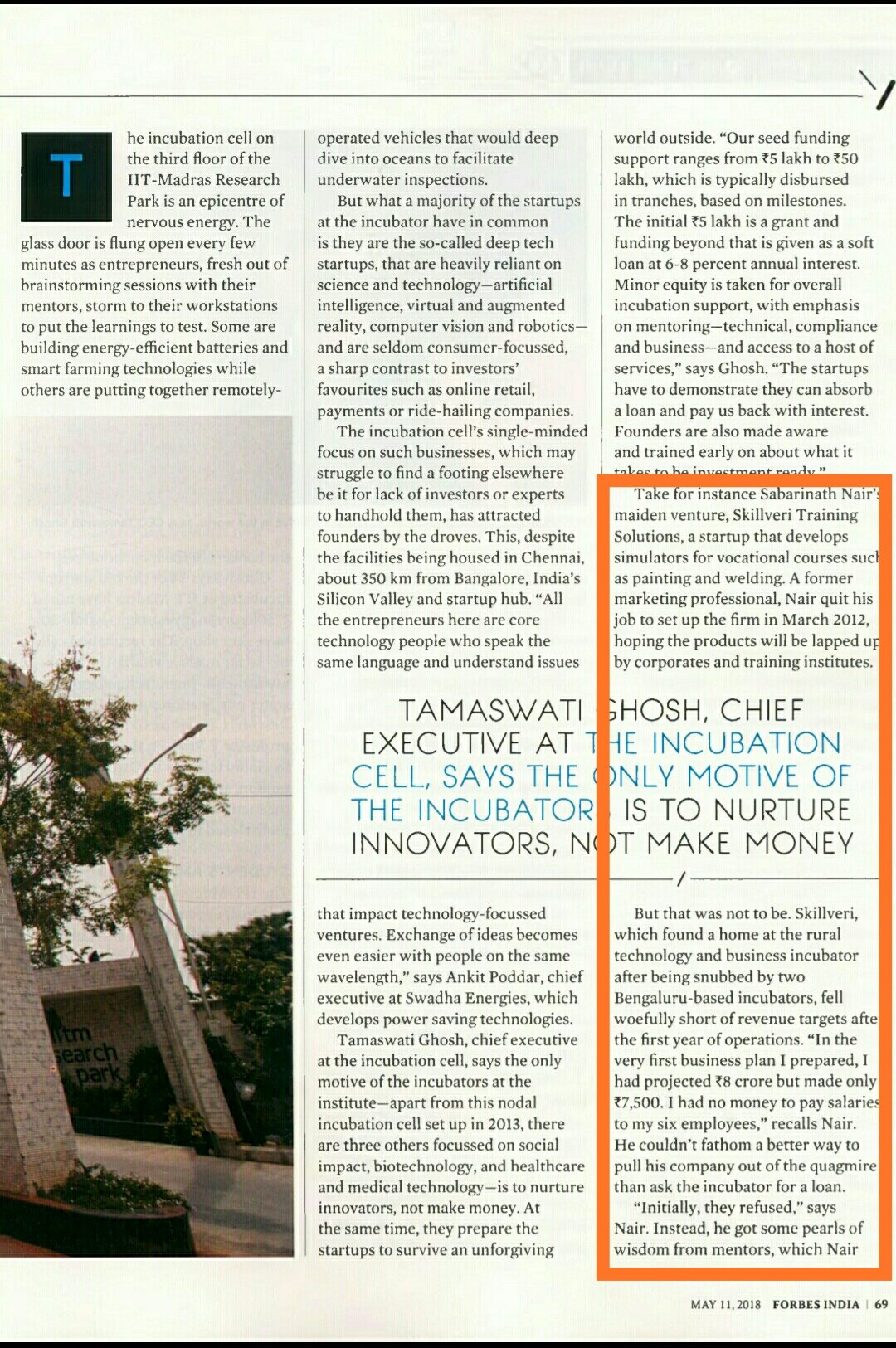

Skillveri featured in Forbes India as part of IIT-Madras incubated successful startups.

” The simulator is mainly for training welders to improve their accuracy and hand skill. A welder can identify his own defects on the job and improve it, while an employer can easily evaluate the potential of his staff. The simulator helps the welder give almost a robotic quality output.”

Coverage about Skillveri in “Naanayam Vikatan” , leading Tamil business magazine, in their series on startups.